Working underwater, especially when you are doing something like welding, brings with it a whole bunch of things that could go wrong. It's not just about getting wet; it's about facing a lot of possible trouble in a very different kind of workplace. Every single job done beneath the surface carries a certain amount of uncertainty, and that uncertainty often points to outcomes nobody wants. You see, the very meaning of risk, at its core, is the possibility of something bad happening, like a loss or even an injury, and that idea really sticks when we think about this kind of work.

When people talk about risk, they sometimes mean something very specific, and other times they mean something much broader, more like a general chance of things going astray. What's common to most of these ways of thinking about risk, though, is that there is always some doubt about what will happen, and often, what might happen isn't good at all. For those who spend their days welding under the water, this means thinking about every little thing that could go wrong, from the smallest hiccup to something truly serious, like a big accident. It's a job where you are, in a way, always dealing with things that are not quite certain, and that is a pretty big part of what risk is all about, basically.

So, considering all this, when we look at underwater welding, we're not just looking at a job; we're looking at an activity surrounded by many chances for things to turn out differently than planned, often in a less than ideal way. This kind of work is, you know, a clear example of how all sorts of efforts are wrapped up in risk. The benefits of doing this kind of work, like fixing pipelines or ships, are often quite big, but we always have to weigh those good things against the potential for something bad to happen. It's about figuring out the possible downsides and getting ready for them, which is a big piece of staying safe and getting the job done right, at the end of the day.

- When Will Mcrib Be Back In 2024 Unraveling The Mystery

- The Enigma Of Opra A Journey Through Life And Legacy

- Celebrating The Life And Legacy Of Mac Miller On His Birthday

- The Shiloh Jolie Pitt Identity The Journey Of A Young Icon

- Exploring The Enigmatic World Of Hazbin Hotel Lute

Table of Contents

- What are the risks of underwater welding – The Basics?

- How does the environment add to the risks of underwater welding?

- What health risks come with underwater welding?

- Are there equipment risks in underwater welding?

- Understanding What Risk Means for Underwater Welding

- Spotting the dangers in underwater welding

- Keeping Safe – Managing the Risks of Underwater Welding

- The Human Element and the risks of underwater welding

What are the risks of underwater welding – The Basics?

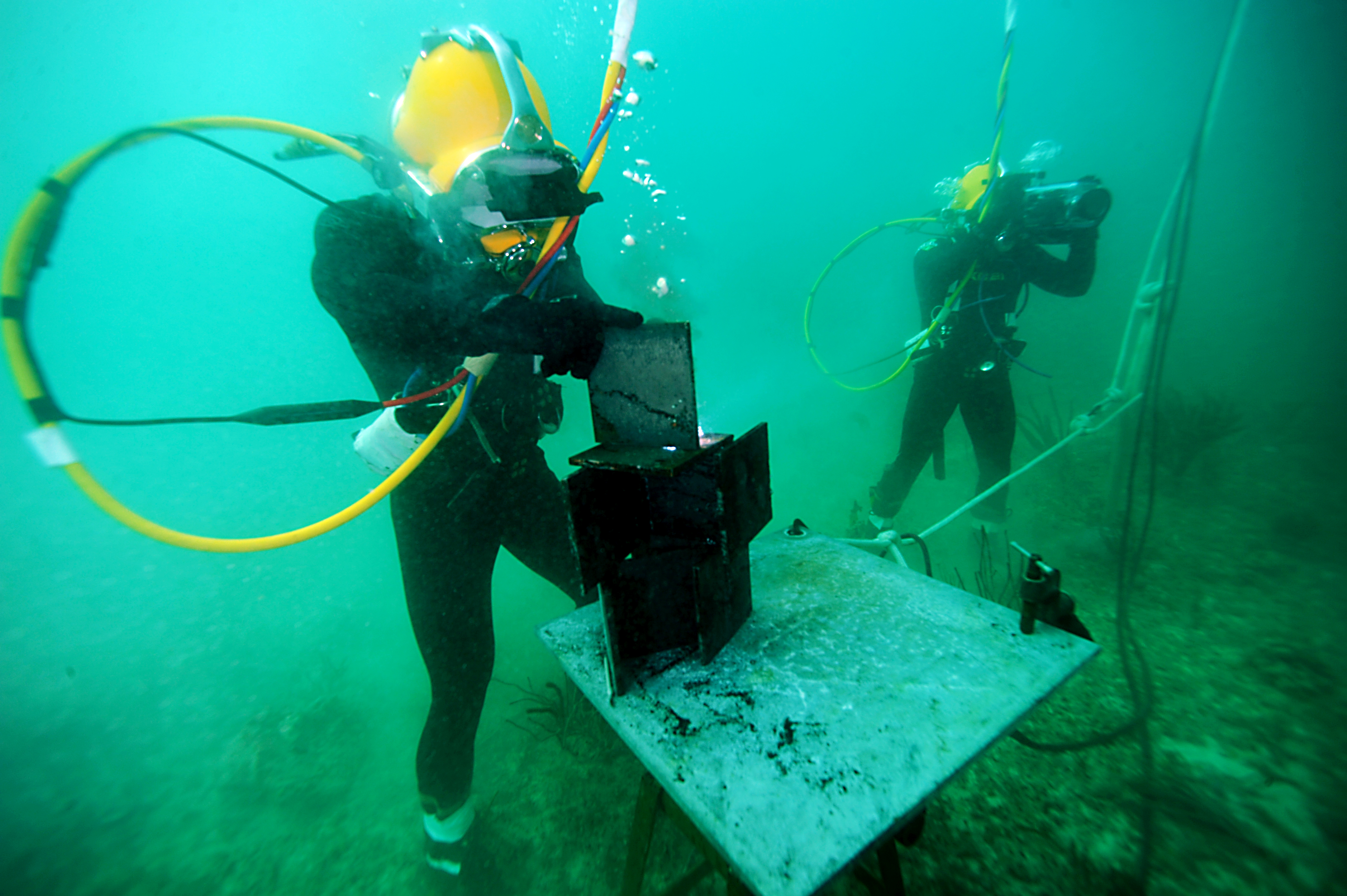

When we talk about what could go wrong with underwater welding, we're really talking about the possibility of something bad happening, like a loss or a physical hurt. This job, you know, is one where you are constantly dealing with things that are not entirely certain. Every action, or even not doing something, has the potential for a negative result. Think about it: a welder is submerged, often in dark, cold water, using tools that are usually quite dangerous on dry land. The simple act of combining electricity with water is, well, a pretty serious source of potential trouble. The chance of getting an electric shock, for instance, is a big one, because electricity and water usually do not mix well at all. This kind of potential for loss or injury is a fundamental part of what risk means, and it's something that is very much present in this line of work, actually.

Beyond just the shock, there is the ever-present danger of drowning. If a piece of equipment fails, or if a diver gets tangled, the water itself becomes a huge threat. Decompression sickness, often called "the bends," is another major concern. This happens when a diver comes up to the surface too quickly, causing gases in their body to form bubbles, which can cause real pain and serious harm. Then there is barotrauma, which is basically injury from pressure changes, affecting ears or sinuses, or even lungs. Being in cold water for a long time can lead to hypothermia, where your body loses heat too fast. All these things represent possibilities of loss or injury, which is, you know, a very clear picture of what risk is all about in this context.

The definitions of risk, you see, can be quite narrow or quite wide, but for underwater welding, they tend to be pretty wide because there are so many things that can cause problems. It's not just about the welding torch; it's about the whole setting. There are dangers from marine life, like getting stung or bitten, though that is perhaps less common than other things. There is also the possibility of getting hit by something, like a piece of equipment or even debris moving in the water. These are all specific possibilities of loss or injury, and figuring out what they are is a big step in trying to keep everyone safe, at the end of the day.

- Unraveling The Mystery The Allure Of The Castle Tv Series

- The Connection Madeleine White And Leo Howard

- Exploring The Life Of Di Marias Children A Glimpse Into Family And Fatherhood

- Unraveling The Life And Career Of Patrick Flueger

- The Wealth What Is Ashantis Net Worth

How does the environment add to the risks of underwater welding?

The underwater world itself adds a whole layer of challenges that really make the risks of underwater welding stand out. Imagine trying to do a precise job when you can barely see what you are doing. Poor visibility is a common issue; the water might be murky from stirred-up silt, or it could just be dark down deep. This makes it hard to see your work, hard to see your tools, and even hard to see other team members. This lack of clear sight, you know, increases the possibility of making a mistake or not noticing a danger until it's too late. It is a clear example of how uncertainty, a core part of risk, plays a role in this environment.

Strong currents are another big environmental factor that really boosts the risks of underwater welding. Imagine trying to hold a steady hand and make a perfect weld when the water around you is pushing and pulling you in different directions. A strong current can move tools, push a welder into something dangerous, or even sweep them away from their work site. This is a very real potential for loss or injury, and it's something that crews have to think about very carefully. The water temperature, too, can be extremely cold, leading to hypothermia if a diver's suit or heating system fails. This is a physical threat that can quickly become a serious health risk, as a matter of fact.

Sometimes, underwater welding needs to happen in tight, enclosed spaces, like inside a sunken ship or a pipeline. These confined areas add even more to the risks. Getting in and out can be tricky, and if something goes wrong, getting help to a welder can be very hard. The air supply might get cut off, or there might be dangerous gases that collect. This kind of setting means that the potential for a loss due to an action or even an inaction becomes much greater. The chance that actual results may turn out less favorably than planned is, you know, a constant thought in these kinds of situations. It is a very challenging place to work, to be honest.

What health risks come with underwater welding?

Beyond the immediate dangers, there are quite a few health concerns that contribute to the overall risks of underwater welding. We talked about decompression sickness, or the bends, but that is just one piece of it. Welders are often exposed to fumes and gases that come from the welding process itself. Even though they are underwater, these fumes can still be breathed in, especially if the ventilation system in their helmet isn't working perfectly. Over time, breathing in these substances can cause problems with the lungs or other parts of the body. This is a clear example of how excess body fat is a serious health risk; here, the "impurity of the air" in a way, is a serious health risk, you know.

The extreme pressures involved in working deep underwater can also affect a welder's body in various ways. Beyond barotrauma, there are long-term effects on bones and joints from repeated pressure changes. The constant cold, even with heated suits, can put a strain on the body's systems over years of work. There is also the potential for hearing damage from loud noises underwater, which can be hard to avoid. These are all possibilities of loss or injury that might not show up right away but can really affect a person's well-being down the road. It's a bit like how smoking is a risk to your lungs; here, the environment itself carries long-term health possibilities for problems, basically.

Then there is the issue of radiation exposure. Arc welding, even underwater, can create ultraviolet (UV) radiation. While protective gear helps, prolonged exposure over many years could lead to eye problems or skin issues. The combination of physical strain, environmental stress, and exposure to various byproducts of the welding process means that the risks of underwater welding include a whole range of health challenges. This is where the idea of "benefits and drawbacks" really comes into play; the financial benefits of the job need to be weighed against these quite serious health drawbacks, to be honest.

Are there equipment risks in underwater welding?

Absolutely, equipment issues add a very significant layer to the risks of underwater welding. Think about all the gear a welder needs: the helmet, the air supply, the umbilical cord that carries power and gas, the welding torch itself, and the safety lines. If any single piece of this equipment malfunctions, it can immediately create a serious situation. For instance, a problem with the air supply could mean a welder runs out of breathable gas, which is, well, a pretty terrifying possibility of loss or injury. A leak in the umbilical cord could lead to an electric shock or a loss of gas, both of which are very bad outcomes, basically.

The tools themselves, like the welding torch, can fail. An electrical short in the torch could cause a shock, or it might just stop working, leaving the welder in a tough spot. Gas leaks from the cylinders or hoses are another big worry; these can be dangerous if the gas is flammable or if it displaces the air a welder needs to breathe. Even seemingly small things, like a faulty pressure gauge, can lead to bigger problems because they give inaccurate information, making it harder to make good decisions. This is where the concept of "potential for a loss due to an action or inaction" really comes to life; a faulty piece of equipment is a hazard, and the risk is the possibility of harm from it, you know.

Maintaining all this gear is a massive undertaking, and if proper checks aren't done, the chances of something going wrong go way up. A worn cable, a corroded connection, or a seal that is not quite right can all lead to equipment failure. This is where risk management, which is about spotting, figuring out, and making less bad the threats, becomes so important. If the equipment is not kept in top shape, then the possibility that the actual results of a decision (like going ahead with a weld) may turn out differently, often less favorably, than what was originally thought, becomes much higher. It's an awful risk to take if you don't keep the equipment in good shape, to be honest.

Understanding What Risk Means for Underwater Welding

When we look at underwater welding, understanding what "risk" truly means is very important. It is, at its heart, the possibility of something undesirable happening, like a loss or an injury. This is not just a vague idea; it is a very real potential for things to go wrong because of something someone does, or even something they do not do. In this line of work, every single move, every piece of equipment, and every environmental factor has this inherent possibility of leading to a bad outcome. The very definition of risk, as the potential for a loss, is a fundamental aspect of all things, especially when uncertainty is involved, which it always is underwater, you know.

The ideas of risk can be quite specific or quite broad. For example, a narrow definition might be the chance of an electric shock from a specific faulty cable. A broader definition would cover all the general dangers of working in a high-pressure, low-visibility, cold environment with heavy machinery. Both of these ways of looking at risk are valid and need to be considered. The important thing is that both point to uncertainty and undesirable outcomes. This means that for underwater welding, there are many different kinds of possibilities for trouble, some small and some very big, basically.

It is also worth noting the difference between a "hazard" and a "risk." A hazard is the source of potential harm. For underwater welding, a hazard could be the electricity, the deep water, or a strong current. The risk, however, is the possibility of loss or injury that comes from that hazard. So, the electric cable is a hazard, but the risk is the possibility of getting shocked from it. The cold water is a hazard, but the risk is the possibility of hypothermia. Being able to tell the difference between these two things helps people better understand and manage the dangers involved, you see.

Spotting the dangers in underwater welding

A big part of dealing with the risks of underwater welding is being able to spot them in the first place. This is where something called risk management comes in, which is a way of systematically figuring out, looking at, and lessening threats or things that are not certain that could affect the job. For underwater welding, this means looking at every part of the operation, from the training of the welders to the condition of the equipment, to the specific conditions of the work site. You have to ask yourself, "What could possibly go wrong here?" and then, "How likely is it to happen, and how bad would it be if it did?" This systematic process is very important, basically.

Identifying dangers in underwater welding involves thinking about all the things we have talked about: the physical dangers like electric shock or drowning, the environmental factors like poor visibility and strong currents, and the equipment itself. It also includes thinking about the human element, like if a welder is tired or not properly trained. All these things represent "threats or uncertainties that can affect your organization," or in this case, the safety of the welding team. You really need to consider them when thinking about how to handle things, to be honest.

These possibilities of trouble can be looked at in different ways, some very specific with numbers, and others more general descriptions. For example, you might say there is a "high chance" of something happening, or you might give a percentage. They can also include both good and bad things, though in the context of danger, we are mostly focused on the bad. Being able to clearly list these possibilities of loss or injury, perhaps in a table, helps everyone involved understand what they are up against. This kind of clear thinking is a big part of making sure everyone knows what they are getting into, you know.

Keeping Safe – Managing the Risks of Underwater Welding

Once you have a good idea of what the risks of underwater welding are, the next step is figuring out how to keep everyone safe. This is where the "mitigating" part of risk management comes in – making the threats less bad. It is about taking steps to reduce the possibility of loss or injury. For underwater welding, this means having very strict safety rules, making sure everyone gets a lot of training, and using the right gear. For instance, making sure all electrical connections are properly insulated and tested before every job significantly lowers the chance of electric shock. This is about making sure the benefits of the treatment, or in this case, the work, far outweigh any risks, you know.

One key way to manage these possibilities for trouble is through really good training. Welders need to know exactly how to use their equipment, how to react in an emergency, and how to work safely in different underwater conditions. They also need to be able to spot hazards themselves and understand the potential for things to go wrong. Regular equipment checks are also a big deal. Every piece of gear, from the helmet to the air tanks, needs to be inspected very carefully to make sure it is working right. This helps prevent equipment failure, which, as we have seen, can lead to very serious possibilities of loss or injury, basically.

Communication is another big piece of the puzzle. The team on the surface needs to be in constant contact with the welder below, and the welder needs to be able to report any issues immediately. Having clear plans for what to do if something goes wrong, like an emergency ascent procedure or a rescue plan, is also very important. This systematic process of identifying, looking at, and making less bad the threats or uncertainties is what helps keep everyone as safe as possible. You are essentially trying to make sure that the actual results of the work do not turn out less favorably than what was hoped for, to be honest.

The Human Element and the risks of underwater welding

The people involved in underwater welding play a huge role in how the risks of underwater welding are handled. Even with the best equipment and the clearest rules, human actions can either make things safer or introduce new possibilities for problems. Things like fatigue, stress, or even just a moment of not paying attention can lead to mistakes. A welder who is tired might not notice a small leak, or a surface crew member might misread a gauge. This is where the idea of "potential for a loss due to an action or inaction" really comes into play, you know.

Proper training, as mentioned, is a big part of addressing the human element. But it is also about making sure people are well-rested, focused, and working together as a team. Miscommunication between the welder and the surface support can be a serious source of trouble. If instructions are unclear or if an emergency message is not understood, the possibilities for loss or injury go way up. This is why clear communication protocols and regular practice drills are so important. It is about building a team that can work together smoothly, even under pressure, basically.

Sometimes, people might take chances, thinking "it will be fine." Kids think it's fun, but they do not realize the risks involved, and sometimes even grown-ups might underestimate the possibilities for problems. This kind of thinking can be a very serious risk in itself. It is about being prepared to put your children at risk in a way, if you are not careful. The goal is to encourage everyone to use wearables to track health metrics, and to think about the benefits and drawbacks of every choice. Taking a risk means doing something even though you know something bad could happen. For underwater welding, the idea is that you have no right to take risks with others, and that means everyone on the team has to be very serious about safety, to be honest.

- The Life And Career Of Keith Bynum Insights From His Wikipedia Page

- The Life Of Wanya Morriss Wife A Journey Of Love And Support

- Exploring The Magnificent 198 Lb Burmese Python

- Cole Barnett A Rising Star In The Entertainment Industry

- Drew Scotts Legacy Remembering The Life And Contributions Of A Beloved Celebrity